Senior Design Project: Home Page

Team 7: Tiny House for Oil Field Workers

| Students (L-R) |

|

| Faculty Advisor |

|

| Instructor(s) |

|

Contents

Welcome

Welcome! We are team # 7, “The 5 Mechanics.” Our project is to design a tiny house for oil field workers.

Oil field workers often have to relocate for work and are away for months at a time during which they would need to seek housing arrangements. Conventional housing arrangement can get pricy and eat away at the earnings of the workers. Other solutions for housing are available such as campers or RVs, but there are some tradeoffs in exchange for a mobile solution. The tiny house movement has gained popularity over the years as more people are looking to downsize their living spaces. The benefits of downsized living are increased savings, it is more environmentally friendly due to tiny living using less resources, the tiny house is also mobile allowing the worker to hitch it to a truck and take it with them. The aim of this project is to provide an affordable housing solution for oil field workers with the addition of being a mostly self-sustaining home. We hope you enjoy this project as much as did.

What is the problem we are trying to solve?

Rent for many traveling workers comes at a high price and not a very pleasant living. Other more mobile solutions offered by competitors such as RVs and campers and even other tiny home manufacturers are also very pricy. Our Tiny House project aims to provide an affordable and enjoyable living for many of these hard workers. Not only would they be able to move it from job site to job site, but also have a friendly impact in the environment.

|

|

Important to know

To better understand the problem, we conducted a background research on relevant topics for our Tiny House, from this we learned the following:

An ergonomic approach: When tackling human needs in the Tiny House we as a team need to understand that the human body has certain basic movements that we have to take into consideration when building the Tiny House because it can ultimately affect our design process.

It is important to know that since we are dealing with an oil field worker, he/she is going to want to be able to come home to a comfortable bed to get some rest and a good size shower after a long day at work.

The overall design of the Tiny House is complex because we are going to provide all the essential needs along with trying to keep it economically affordable to the oil field worker. In doing so as a team we encounter that there so many different types of appliances/products for sale that we had to put together the right combination in order to fit the Tiny House dimensions while also providing the essential needs of the oil field worker.

We as a team understand that there is better, fancier products out in the market however, our Tiny House is going to be self-sustainable, meaning that the house will not need another source of power besides its own. This strategy is perfect for the oil field worker because they are going to be able to park anywhere (as long as the place permits) and rest for the night. Compared to a regular RV/Trailer Home where they are eventually going to need an outside power source.

Current solutions include travelling RVs that have a multitude of uses that ranged from campers to beachside homes during the summer. The use of RVs is the current solution to some travelling workers or outdoor goers. One notable example is the 2019 Jayco Hummingbird 10RK due to the small space while able to provide most of what a consumer would need to travel.

Other solutions include more luxury/expensive tiny houses that are built custom by select few companies. These types of tiny houses are not built on the basis of renewable energy and are marked upwards of $70,000. Our tiny house will tackle the above challenges and at an affordable price.

Why is this problem important?

Our main motivation to work on this project was to offer an alternative solution to the housing problem traveling workers often face since they have to constantly relocate due to the nature of their jobs. A lot of these workers often have to share houses and due to the high demand of places to stay and not enough supply, the prices for these places tend to increase from season to season; this creates a significant problem for many of these workers. The idea of offering an alternative option such as an affordable tiny house that also provides all the essentials to have a comforting living put us to work on the design of one that included all these characteristics.

Our proposed solution

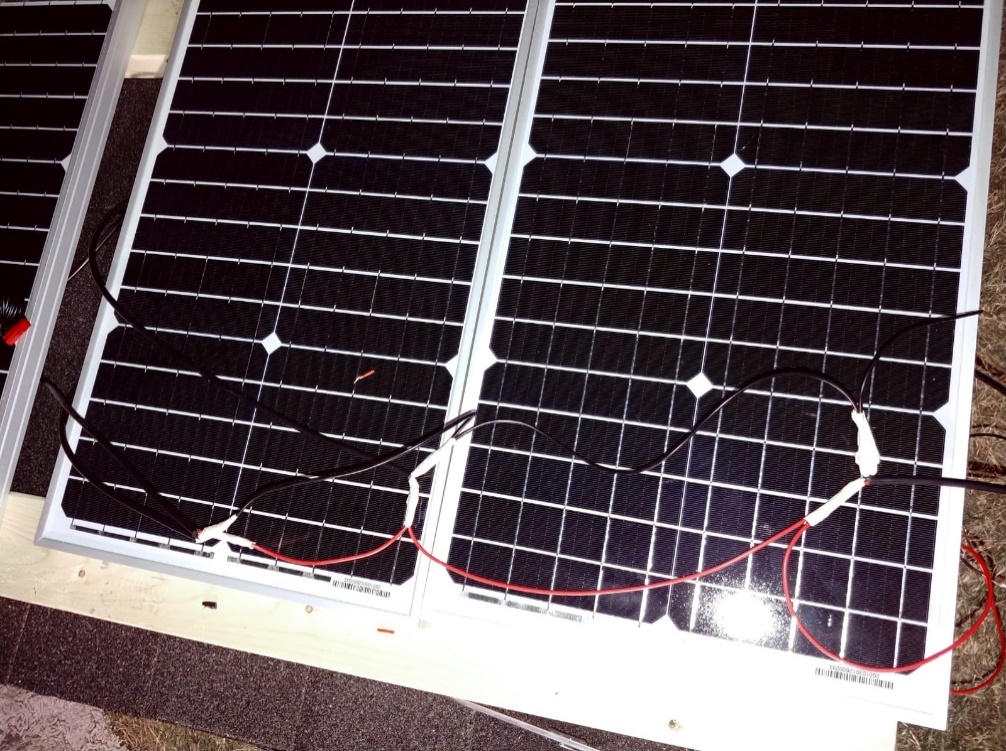

“Our propose is a redesigned concept of the tiny house that contemplates the efficient use of space, new construction methods, and the use of renewable sources of energy such as solar panels."

After careful consideration of various designs and alternatives, we decided to create a design that followed the new standards of construction for energy efficiency to minimize the consumption of power and maximize the level of comfort inside the tiny house. The design implemented the use of solar panels in combination with Li-ion Batteries for the storage of power to offer a reliable source of electricity capable enough to power the essential appliances for a comfortable living.

From idea to reality

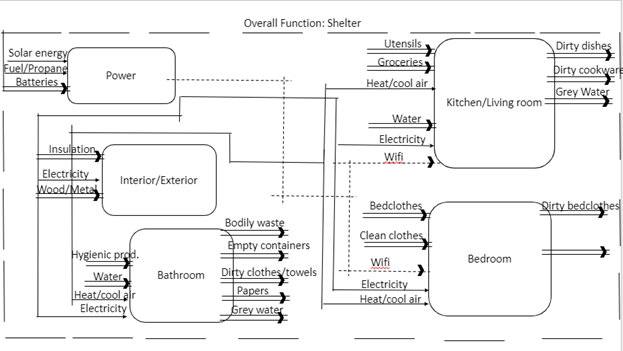

Once we defined a clear solution idea (i.e. concept), we applied our engineering knowledge to transform it into a real working prototype, and soon product. These were some of the important design challenges and how we approached each one of them:

- The internal layout of the tiny house must comfortably fit a variety of human sizes and have convenient areas of the tiny house to relax in.

- Renewable Energy and how efficiently the energy are in use throughout the tiny house.

- Designing the power system

- Designing the water system

To make sure our tiny house was designed with the end users in mind, we made sure to put a focus on how the bed in the tiny house may be adjusted and removed to make space for various recreational activities. Below a figure showing how the tiny house will look and the adjustable murphy bed is shown.

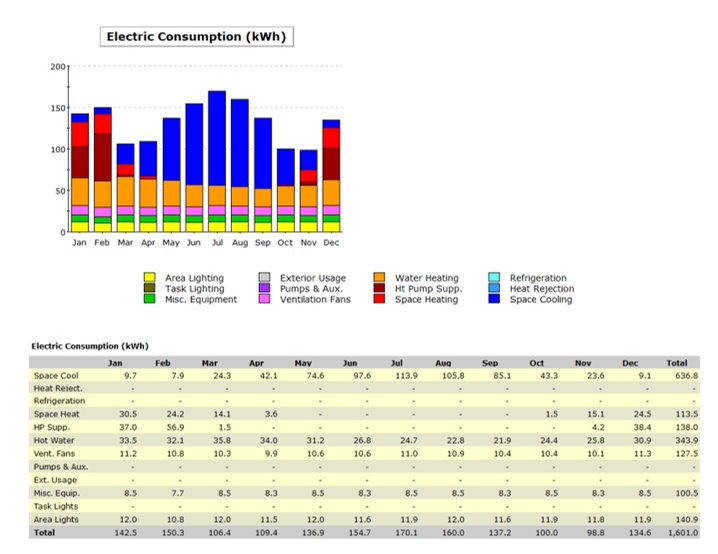

An important figure above shows the typical amount of energy one may use throughout the year. All values derive from given parameters of a normal weekly schedule and located in West Texas. Using the above graph, our group came to a better understanding of how much energy will be in use throughout the tiny house.

One of the goals of the project is to develop a system that can work off the grid, meaning a self-sufficient system. Below is a basic schematic meant to give a visual representation of how the elements of the electrical system will be organized. One of the ways the house will have power is through solar energy, batteries will be used for energy storage. An inverter will be used to convert the DC current from the energy storage into AC because most of the appliances in the house require it. Aside from regular AC wall outlets, outlets that are 12V DC will be provided because some electronic devices or equipment can work directly with DC. The house is not completely run by solar energy though, so a portable gas generator is also part of the system as a backup source.

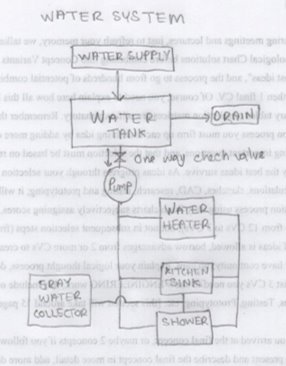

Along with the power system, the team developed the water system for the tiny house. Below is a basic layout for how the water system will work.

The water can be supplied from an RV park or city water system, there is also a tank for reserve water if a source is not available. A tankless water heater is part of the design; the tankless water heater has a higher upfront cost as opposed to the tank water heaters, but the benefit is saving space as well as finding ways to reduce the weight of the tiny home. Another component of the water system is a greywater collector to hold the waste water that comes from the sink and the shower.

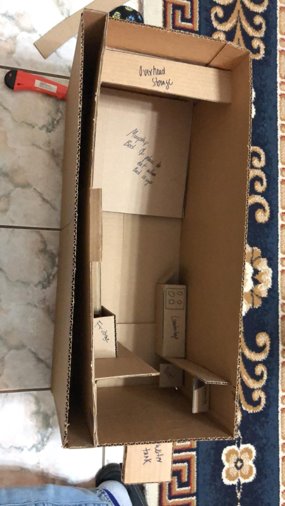

Prototype early and often

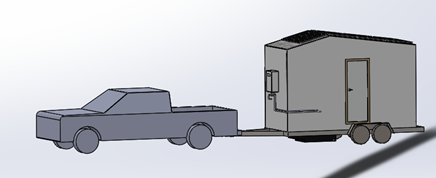

We found that physical prototyping was very important in realizing how a tiny house will look and feel like for the viewer and customer. Starting with basic prototypes, a visual representation of how someone takes up space and how little space was made available was a key aspect when analyzing our prototypes.

This was our first prototype, it may be simple, but it helped us understand how volume was a key factor and space management was important when designing the tiny house. This first prototype allowed us to visually see how the house was going to be constructed because in design we can make everything fit perfectly but it is until actual construction that the problems will arise.

Our second prototype included a more sophisticated design than the previous and included adjustable furniture and a comparison of how someone may look inside one. A visual on the layers of insulation are also observed with a detachable roof.

Final product

Our final prototype (work in progress) will include a physical scaled down model of the SolidWorks model to represent how the final product may look.

The figure above shows the initial setup/membrane of our final prototype. This version is the base of what the final prototype will become.

The figure below shows the front view of the final prototype and a video to show the other views of the prototype.

Future work

Our project is a proof of concept that requires further development, these are some of the pending items:

Full Scale Build: We recommend perhaps modeling it first just so that there is a visual representation to follow and it prevents us from building the tiny house blindly.

Working Parts: Once built, the house could be fully functional with working lights, plumbing, electrical, drainage etc...

In conclusion

Our Senior Design experience was a historical one because mid-way of our senior design the world entered into a global epidemic which halted our senior design process. Everything includes class lectures were switching to online platforms which was ultimately great for the students that had to travel far but not so much for the students that would rather attend school and physically be there in class. Throughout the year in senior design we, as a team, learned that there is so much research, learning, analysis, and discussion when it comes to designing a product from scratch. Learning this, we created tasks to complete to ensure the success of our design. These tasks included customer interviews, utilization of software for visualization, competitive research, and background information to fully understand the potential of our project. The one major thing that could have been different was the fact that we had to switch to an online format where we as a team struggled to meet at moments because some of us lived either far away or were working during the time of the meeting. It would have been great to present our project in front of the whole Mechanical Engineering Department to showcase our hard work and applying what we learned throughout theese four years attending UTRGV. Overall, our Senior Design experience was a great one with the help of our instructors, Dr. Noe V. Hernandez and Gregory Potter, amd our Faculty Advisor, Dr. Stephan Crown, we as a team learned so much from these great professors.

Acknoledgements

The team received help from various persons, their help was critical to our success, we would like to acknowledge our faculty advisor Dr. Stephen Crown for allowing us to take on this project. The team would also like to acknowledge the course advisors Dr. Noe Vargas and Mr. Potter. Dr. Vargas led the team through the design process and introduced us to some techniques whether it was in lecture or through meetings. Mr. Potter was available for prototype meetings and would offer advice as well as give some perspective for the prototyping process. We would also like to acknowledge the business team made up Amanda Guardado, Giovana Longoria, and Kassandra Castillo who we collaborated with for the creation of the business proposal for this project.

The Design Process

This page gave a general summary of our senior design project. Click on the header or on the sidebar to learn about design process we used to design this product.